Sights Unseen: Inside Maine Heritage Weavers

RUSS DILLINGHAM/SUN JOURNAL

Weaver Dot Mcatee checks for a break or tangle in one of the looms. It's a constant process of moving from one loom to another throughout the day, while handling other tasks that keep the machines running at Maine Heritage Weavers in Lewiston.

RUSSELL DILLINGHAM, Staff Photographer

bPlus |

Sunday, October 14, 2012

Many of the workers at Maine Heritage Weavers in Lewiston are doing the same work as their parents and grandparents, and some of them are using the same looms that have been producing quality blankets, bedspreads and other textiles since the early 1800s.

Fred Lebel started working at Bates Mill when he got out of the service in 1952. He worked for Bates until it closed. Not wanting to see the loss of an industry so vital to the history of Lewiston or the skilled workers involved, he bought some of the equipment, patents and patterns, and moved the operation from the Bates Mill across Chestnut Street to the Roy Hill Mill, starting a new venture, Maine Heritage Weaving.

More importantly, along with his daughter, Linda Cloutier, he slowly began hiring back some of the most skilled weavers who worked for him at Bates. Today, Lebel still works every day, but in his own words, "Linda has taken over and does most of the work. I just help out. We have been growing, adding looms and workers, and in a month or two, we will have some very big news that we are excited about."

RUSS DILLINGHAM/SUN JOURNAL

Aaron Sawyer looks for breaks in the lines that are winding around the warper, a large spool that feeds the slasher, which is a larger spool that feeds the giant looms at Maine Heritage Weavers in Lewiston.

RUSS DILLINGHAM/SUN JOURNAL

The paper cards act like a simple computer to ultimately create the patterns in the blankets, bedspreads and other material being woven. The technology has been in use since the early 1800s, with only a few upgrades.

RUSS DILLINGHAM/SUN JOURNAL

Rene Cote looks for a break in the line on the slasher machine at Maine Heritage Weavers in Lewiston.

RUSS DILLINGHAM/SUN JOURNAL

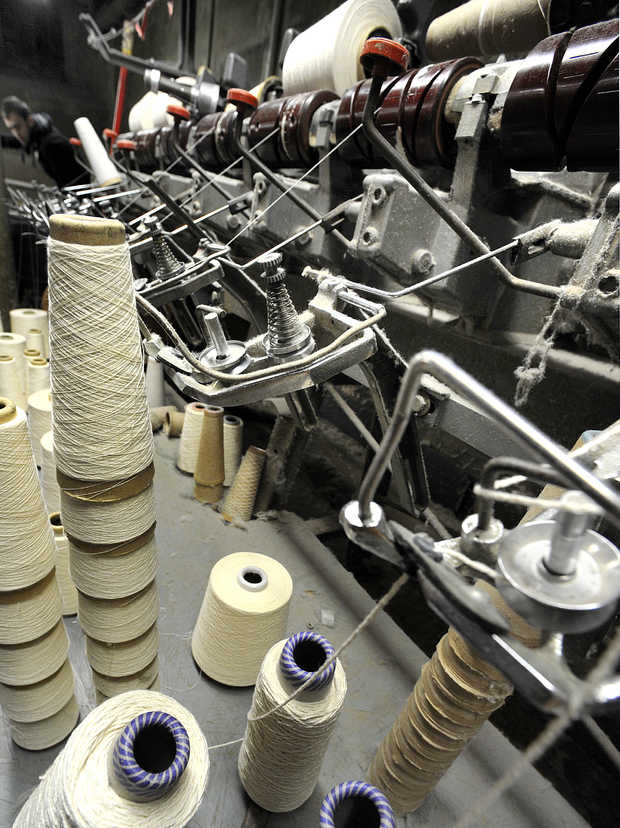

After used bobbins are swapped out for full ones, they are sent downstairs to be spliced together on this machine to create full ones.

RUSS DILLINGHAM/SUN JOURNAL

An old wooden bobbin (they are now made of cardboard) used by weavers to help pull thread into place rests on a loom for easy access at Maine Heritage Weavers in Lewiston.

RUSS DILLINGHAM/SUN JOURNAL

Rolls of fabric await cutting, trimming and finishing at Maine Heritage Weavers in Lewiston.

RUSS DILLINGHAM/SUN JOURNAL

Pillow shams that have been washed await trimming, finishing and packaging at Maine Heritage Weavers in Lewiston.

RUSS DILLINGHAM/SUN JOURNAL

Pillow shams that have been washed await trimming, finishing and packaging at Maine Heritage Weavers in Lewiston.

RUSS DILLINGHAM/SUN JOURNAL

Fred Lebel looks out at the looms running at Maine Heritage Weavers in Lewiston, which he and his daughter Linda own.

RUSS DILLINGHAM/SUN JOURNAL

Sue Valonis, right, and her daughter Michelle Boilard fold an Abigail Adams bedspread at Maine Heritage Weavers in Lewiston.

Aaron Sawyer looks for breaks in the lines that are winding around the warper, a large spool that feeds the slasher, which is a larger spool that feeds the giant looms at Maine Heritage Weavers in Lewiston. |RUSS DILLINGHAM/SUN JOURNAL

The paper cards act like a simple computer to ultimately create the patterns in the blankets, bedspreads and other material being woven. The technology has been in use since the early 1800s, with only a few upgrades. | RUSS DILLINGHAM/SUN JOURNAL

Rene Cote looks for a break in the line on the slasher machine at Maine Heritage Weavers in Lewiston. | RUSS DILLINGHAM/SUN JOURNAL

After used bobbins are swapped out for full ones, they are sent downstairs to be spliced together on this machine to create full ones. | RUSS DILLINGHAM/SUN JOURNAL

An old wooden bobbin (they are now made of cardboard) used by weavers to help pull thread into place rests on a loom for easy access at Maine Heritage Weavers in Lewiston. | RUSS DILLINGHAM/SUN JOURNAL

Rolls of fabric await cutting, trimming and finishing at Maine Heritage Weavers in Lewiston. | RUSS DILLINGHAM/SUN JOURNAL

Pillow shams that have been washed await trimming, finishing and packaging at Maine Heritage Weavers in Lewiston. | RUSS DILLINGHAM/SUN JOURNAL

Pillow shams that have been washed await trimming, finishing and packaging at Maine Heritage Weavers in Lewiston. | RUSS DILLINGHAM/SUN JOURNAL

Fred Lebel looks out at the looms running at Maine Heritage Weavers in Lewiston, which he and his daughter Linda own. | RUSS DILLINGHAM/SUN JOURNAL

Sue Valonis, right, and her daughter Michelle Boilard fold an Abigail Adams bedspread at Maine Heritage Weavers in Lewiston. | RUSS DILLINGHAM/SUN JOURNAL